-

الكسندرالموردين الموثوق بهم

الكسندرالموردين الموثوق بهم -

لويسلقد كان من دواعي سروري العمل معك

لويسلقد كان من دواعي سروري العمل معك

مُوفِّر اقتصاد الوقود للمراجل مع إنتاج بخار بحد أقصى 20 طن/ساعة وضمان 5 سنوات على المكونات الأساسية

اتصل بي للحصول على عينات مجانية وكوبونات

الـ (واتس اب):0086 18588475571

(ويتشات): 0086 18588475571

سكايب: sales10@aixton.com

إذا كان لديك أي مخاوف، نحن نقدم المساعدة على الانترنت على مدار 24 ساعة.

x| يكتب | الدورة الدموية الطبيعية | بناء | أنبوب النار وأنبوب الماء |

|---|---|---|---|

| ضغط | ضغط منخفض / مرتفع | إنتاج البخار | Max. الأعلى. 20t/h 20 طن/ساعة |

| أسلوب | رَأسِيّ | وقود | الفحم / الغاز / الفحم / حرارة الماء |

| الإخراج | الماء الساخن / البخار | المعالجة السطحية | رسمت |

| مادة | سبائك الصلب ، الصلب الكربوني ، SA210C ، SA213T22 | معيار المواد | ASTM ، EN أو ISO |

| نطاق الوزن | دقيقة: 10 طن ، الحد الأقصى: 1000 طن | عملية الصهر | EF + LF + VD |

| عملية | Material-> INPOT-> HOT/COLD-ROLLING-> المعالجة الحرارية-> التفتيش-> MACHINING-> UT | معيار UT | ASTM A388 أو EN10228 |

| المعالجة الحرارية | تطبيع+ تقع | ||

| إبراز | أقصى 20 طن/ساعة مكيف لإنتاج البخار,ضمان لمدة سنة واحدة على مُوفِّر غاز العادم,ضمان لمدة 5 سنوات على المكونات الأساسية للمُبادل الحراري,1 Year Warranty Exhaust Gas Economizer,5 Years Core Components Warranty Heat Exchanger |

||

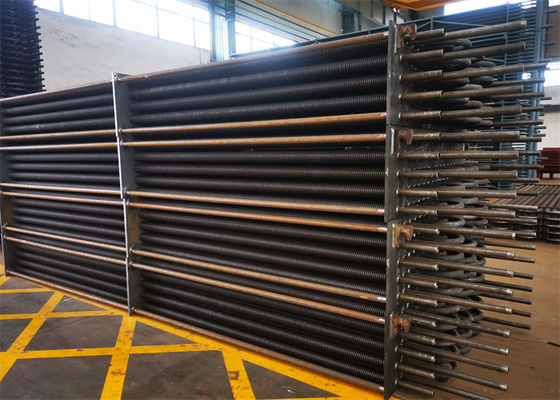

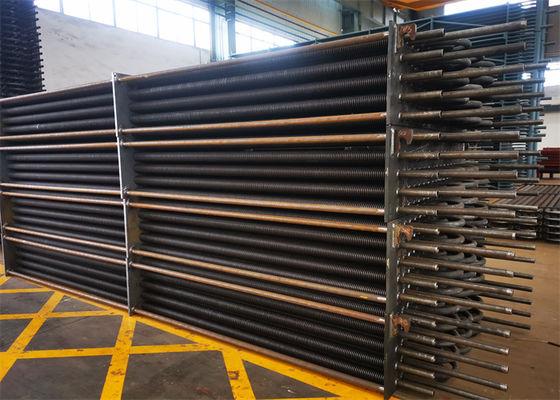

أجهزة التوفير من الغلاية هي أجهزة لتبادل الحرارة عالية الكفاءة مع أنابيب ذات أجنحة مصممة لتسخين السوائل (عادة الماء) دون تجاوز نقطة غليان السائل.نحن ننتج ثلاثة أنواع من المكيفات الغازية:

- أجهزة إقتصاد الأنابيب العارية

- أجهزة إقتصاد الأنابيب ذات الأجنحة H

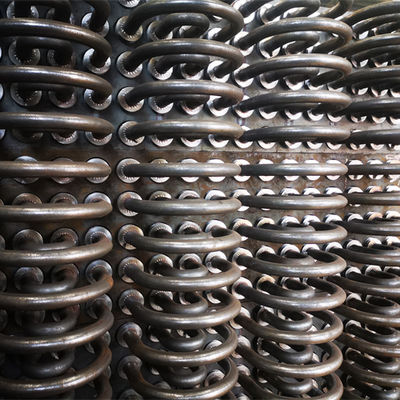

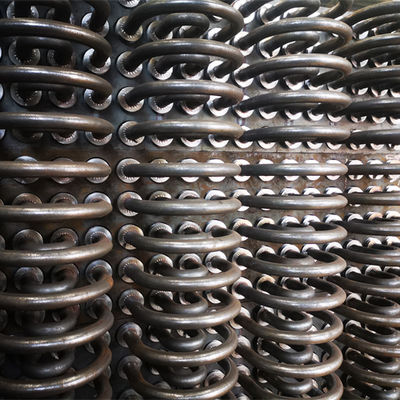

- أجهزة إقتصاد الأنابيب ذات الأجنحة الحلزونية

مُوفّر أنبوب H-fined هو مُبادل حرارة فعال بشكل خاص يتكون من أنابيب H-fined. بالمقارنة مع مُوفّر الأنابيب العارية، توفر النماذج H-fined:

- منطقة التبادل الحراري الموسعة

- عدد قليل من الأنابيب المطلوبة

- مساحة زيادة تدفق غازات الدخان

- انخفاض سرعة تدفق غازات الدخان والتكسير

يحتوي الجهاز على تصميم مبتكر مع أنابيب ذو أجنحة دائرية تتغلب على مشاكل شائعة من الاحتكاك وفترة خدمة قصيرة

كما يوحي الاسم ، فإن الوظيفة الأساسية لجهاز الاقتصاد هي "التوفير" - تقليل تكاليف التبريد بشكل كبير من خلال السماح بإيقاف الضاغط مع الحفاظ على قدرة التبريد الكافية ،مما يؤدي إلى وفورات كبيرة في استخدام الطاقة.

| الوصف | إقتصادي الغلاية |

|---|---|

| المواد | الفولاذ المسبوك، الفولاذ الكربوني، SA210C، SA213T22، الخ |

| معيار المواد | ASTM، EN أو ISO الخ |

| البعد | التخصيص |

| الوزن | الحد الأدنى: 10 طن الحد الأقصى: 1000 طن |

| عملية الصهر | EF + LF + VD |

| العملية | المواد→الإنجوت→التحرير الساخن/البارد→معالجة الحرارة (التطبيع + التشديد)→التفتيش→التشغيل الخام→التشغيل الخام→التشغيل الثاني |

| معيار UT | ASTM A388 أو EN10228، الخ |

- تقرير اختبار الأثر وحساب المقاومة مع معلومات المواد المطبقة

- تقرير 100% NDT (التفتيش غير المدمر) للصفائح والأنابيب والإلكترودات الصلبة

- تقرير الفحص بالأشعة السينية والشعاع الـ γ ومتطلبات اختبار الاختراق السائل (خيط اللحام) لضمان جودة المرجل الكاملة

- تقرير الاختبار الهيدروليكي للتحقق من ضغط العمل القياسي والسلامة